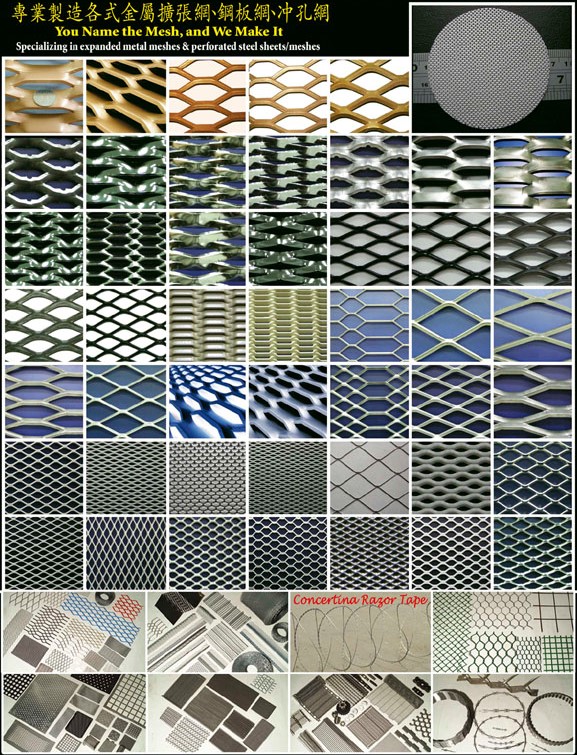

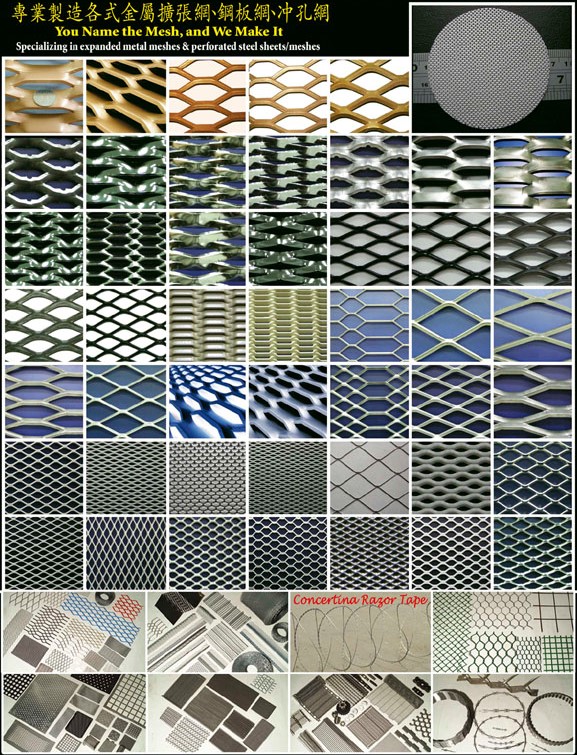

maquinas para fabricar metal desplegado, Perforated Metal, Perforated Metal Manufacturer,

Perforated Metal Manufacturers,expanded metal machinery, perforated metal panel,

Corner Bead, Angle bead, construction machinery, construction machinery

equipment, perforated metal, cornenite, perforated metal supplier, perforated

metal manufacturer, perforated panel, perforated plate, perforated steel plate,

expanded metal machine, expanded metal, expanded metal mesh, Compresser,

splitter

Inquiry

Contact

Español

¡@

Maquinas para fabricar metal

desplegado:

A Leading Manufacturer in

Perforated

Metal Machine/Automatic Net Making Machine/

Dual-Bearing NC/CNC Automatic Feeding High Speed

Screen Pressing Machine/

Sheet Metal Punching Press Machine/Expanded Metal

Making Machine/Expanded Metal/Checkered Plate Machinery

¡@

|

Description

We offer of Dual-Bearing NC Automatic Feeding High Speed

Screen Press, Deep Throat Dual-bearing NC Automatic feeding high speed Screen

Press, Straight-Axle Powerful Steel-Made Pneumatic Screen Press.

Perforated mesh is a

product that has been widely used in various areas, including construction,

remodeling, air filter on the ceiling, isolation, kitchen utensils, stereo

system and lawn furniture.

as a leading manufacturer in the metal mesh industry, is committed to its

customers to produce top quality machinery at a very competitive price. Our

machinery can produce the patterns that will meet your requirements, such as

round, rectangle, square, etc. (see the following Finished Products.)

Our R&D team has devoted their time and talent to design the machinery that is

more efficient.

You can count on our good reputation in this field.

Products:

Dual-Bearing NC Automatic Feeding High Speed Screen Press,

Deep Throat Dual-bearing NC Automatic feeding high speed Screen Press,

Straight-Axle Powerful Steel-Made Pneumatic Screen Press

¡@

¡@

|

¡@

Semi-Auto

Checkered Plate Production Line/Checkered Plate Min Machine/

Perforated

Metal Machine/Fully (Semi)

Automatic Net Making Machine/

Deep Throat Dual-Bearing NC-CNC

Automatic Feeding High Speed Screen Pressing Machine/

Automotive Production Line With Auto

feeding System For Manufacturing Cable Tray Perforated Sheet

automatic_net_making_machine.jpg)

Specification :

1. Thickness : 0.4~8.0mm

2. S.P.M : 0~120Products This machine is suitable for the market which

needs various patterns. The easy-changing punch dies can save a lot of time

when on changin mould. Also, saving much investment on different moulds, if

you required large range on material thickness. The perforated metel m/c is

your best choice. |

Description:

Fully(Semi)Automatic Net Making Machine

/ Semi-Automatic Perforated Metal Making Machine (Throat Type) Wind of

lathing:1000m/m1220m/m

-

The body is made by adopting with

strong steel plate and is assembled in welding. It can bear great impact after

being absorbed by stress. So it will not deformed forever.

-

Finished Product Size: 4*10 feet

-

Suitable Material: Stainless Steel,

Hot Rolled Black Steel, Aluminum....Special Material is WELCOME.

-

Minimum Punching Hole Diameter:

0.5mm

-

The Main Bearing and Connecting

Bearing have been coated with PHOSPHOR BRONZE which will increase the wear

feature of machine as driving with high speed.

-

Deep-Throat, Dual-Bearing,

Automation.

-

Punching Ability: 150~200 Ton

-

Reciprocating operation

-

Manpower saving

-

Automatic filling lubrication

-

Automatic process from feeding to

finish products

-

This machine is suitable for the market which needs various

patterns. The easy-changing punch dies can save a lot of time when on

changing mould. Also, saving much investment on different moulds, if you

required large range on material thickness. The perforated metal machine is your

best choice.

MOLD/TOOLING

¡@

Application:

Spinning, Wearing,

Building, Machine, Plywood, Coal Tar, Electron, Glassware, Heat

Treatment, Leather, Plastic flowers, Earthenware/Pottery/Crockery, Cast Iron,

Printing Skill, Nicotine Weed/Tobacco, Rubber, Chemical, Mineral, Paper

Industry, Pharmacy, Metal Industry, Ceramics, Bottle Industry, Cement,

Grocery Industry and others.....

Products:

Maquinas

para fabricar metal desplegado

¡@

Rhomb Expanding Net Machine (CF-96

& CF60)

Type: Automatic Expanded Metal Making Machine |

|

| Description: |

|

Rhomb Expanding Net Machine(CF-96

|

- WIND OF LATHING:1220m/m~2440m/m

- SPM:100~300

- THICKNESS:8.0mm Max

- MOTOR:15-30hp

|

|

¡@ |

¡@ |

Function:

- Speaker Net

- Air/Oil Filler

- Ornamental Net

- Emectric fan Net

- B.B.Q Net

- Radar Net

- Security Fence

- Construction Net

- Industrial Net

- Catwalk. others

¡@ |

Products

¡@ |

|

TYPE

|

WIDTH

|

SPM

|

THICKNESS

|

SW

|

MOTOR

|

|

CF-012

|

12"max

|

800~1000

|

0.7mm max

|

4mm max

|

3hp

|

|

CF-024

|

24"max

|

500~800

|

1.0mm max

|

10mm max

|

5hp

|

|

CF-040

|

40"max

|

200~300

|

1.6mm max

|

14mm max

|

7.5hp

|

|

CF-048

|

48"max

|

100~300 |

3.0mm max

|

34mm max

|

10-20hp

|

|

CF-096

|

96"max

|

100~300

|

8.0mm max

|

40mm max

|

15-30hp

|

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

¡@

Plano-Type Perforated Metal

Machine/Dual-Bearing NC/CNC Automatic Feeding High Speed Scree Pressing Machine

Description:

-

The body is made by adopting with

strong steel plate and is assembled in welding. It can bear great impact after

being absorbed by stress. So it will not deformed forever.

-

Finished Product Size: 5*10 feet

-

Suitable Material: Stainless Steel,

Hot Rolled Black Steel, Aluminum....Special Material is WELCOME.

-

Minimum Punching Hole Diameter:

0.5mm

-

The Main Bearing and Connecting

Bearing have been coated with PHOSPHOR BRONZE which will increase the wear

feature of machine as driving with high speed.

-

Deep-Throat, Dual-Bearing,

Automation.

-

Punching Ability: 200~500 Ton, MAX FEED:250 STROKES/MINUTE

-

Reciprocating operation

-

Manpower saving

-

Automatic filling lubrication

-

Automatic process from feeding to

finish products

-

This machine is suitable for the market which needs various

patterns. The easy-changing punch dies can save a lot of time when on

changing mould. Also, saving much investment on different moulds, if you

required large range on material thickness. The perforated metal machine is your

best choice.

Three machines jointed as one set including Main Unit+Material Feeding Machine+Cutting

Machine. High precision, low cost,

smaller space occupation, suitable for mass-production purpose rolling, boring and

cutting functions

¡@

Automatic Perforated Metal Making

Machines (Plano Type)

Model: CF-5000 CF-8000 CF-10000 CF-12500 CF-15250 |

¡@

| Description: |

|

Automatic Perforated Metal Making Machines

(Plano Type)

|

Piano-type automatic perforated metal making machine, produce various

kinds of machinery of the perforated metal net.

|

Specification :

1. Steel

coil thickness: 0.5~2.0mm Max.

2. Steel coil width: 1,250mm Max.

3. Perforated net hole diameter: Diameter 2.0~10.0mm.

4. Working space required: about 3M X 7M.

5. Applicable material: various kinds of metal sheets.

6. Motor: 20~30Hp.

7. Voltage: 220/380/420.

8. S.P.M: 60~150/Min.

9. Thickness : 0.4~3.0mm

10. S.P.M : 0~200

|

|

Rhombus network

|

Description: |

|

PS:All specifications can be ordered and

made. Welcome to contact with us. |

¡@

Wash the hole network

|

¡@

¡@

¡@

¡@

¡@

¡@

Checkered Plate (5 claws) / Checkered Plate (Rice Pattern) |

|

Description: |

|

|

NUMBER |

|

|

|

|

|

|

EXS

.

Network of

Sparkler |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@ ¡@

PS: All specifications can be ordered and made. Welcome to

contact with us. |

Line / Rib-Lath / Hi Rib-Lath Making Machine

Angle Bead / CORNER BEAD / Plaster Stop Bead Production

|

| PLASTER STOP BEADS 1

|

PLASTER STOP BEADS 2

|

PLASTER STOP BEADS 3

|

PLASTER STOP BEADS 4

|

|

| PLASTER STOP BEADS 5

|

PLASTER STOP BEADS 6

|

PLASTER STOP BEADS 7

|

PLASTER STOP BEADS 8

|

Metal Mesh Forming Making Machine

¡@

Cable Tray Swaging Making Forming Machine

|

Description: |

¡@ |

3-Leveller / Leveling Machine

|

-

WIDTH : 96" WIND OF LATHING : 2440mm Max

-

Application: Levels off the end product either (or end product)

flatness puts in order the raw material to wants the radian

|

|

Straight-Axle Powerful Steel-Made

Pneumatic Screen Press

¡@

Description:

-

The body is made by adopting with

strong steel plate and is assembled in welding. It can bear great impact after

being absorbed by stress. So it will not deformed forever.

-

Suitable Material: Stainless Steel,

Hot Rolled Black Steel, Aluminum....Special Material is WELCOME.

-

Minimum Punching Hole Diameter:

0.5mm

-

The Main Bearing and Connecting

Bearing have been coated with PHOSPHOR BRONZE which will increase the wear

feature of machine as driving with high speed.

-

This machine can be designed with

Auto or Semi-Auto type upon customer's different requirements. It's operation

may be processed by adopting with Pedal Brake Electronic Switch. Easy and

Comfortable.

-

The stroke is rapid. The main Motor

can be applied with Transmission Motor (Variable

Speed Motor) so as to promote the output and reduce the loss of the

mold.

-

We are specialized in making

products with various specifications upon your request so as to meet

requirements of various works.

|

Model |

DEEP 100 |

DEEP 120 |

DEEP 130 |

DEEP 150 |

DEEP 200 |

|

Punching Ability (Ton) |

100T |

120T |

130T |

150T |

200T |

|

Stroke |

45 |

50 |

50 |

55 |

55 |

|

Stroke/minute |

120 |

120 |

110 |

100 |

90 |

|

Max. Working Height |

210 |

230 |

230 |

250 |

250 |

|

Slide Bore |

50 |

50 |

50 |

50 |

50 |

|

Slide Q'ty Adjustment |

50 |

|

Platform Area |

455*950 |

455*1100 |

455*1120 |

455*1120 |

500*1250 |

|

Opening |

200*1325 |

200*1325 |

200*1485 |

200*1540 |

200*1540 |

|

Variable Speed Motor (HP) |

10 |

15 |

15 |

15 |

20 |

|

Weight (kg) |

13200 |

18500 |

21000 |

24000 |

27000 |

¡@

Super Pneumatic Plastic Leather Punching Machine

Description:

-

Plano-Type, High Speed

-

Can feed with Frame Wider

-

The largest width up to 6feet

Portal Type Pneumatic High Speed Pressing Machine

Description:

-

Straight-Arm Steel-Structure

Mechanism: Design of the machine will prevent the product's pressing areas

deformation happened when pressing , which can further ensure a quality

accuracy.

-

Guide Passage, New Design:

Slide Plate of the machine is made of specific precise copper casting. In

addition to 8-direction of guide passage, which is specially good in abrasion

resistance.

-

Slide Adjusting System: The

height adjusting mechanism is digital sight, the loss devise is made with

hydraulic air system. Easy operation and excellent efficiency.

-

Mechanical Template Blocking

Device: If any template blocking happened while pressing, the mechanism

can quickly and efficiently act trouble shooting for user.

-

Motor Speed Adjustment System:

Speed System of the machine is made in a converter design. High efficiency and

can further save energy.

-

Oiling System: The oil ways

of the machine is designed as return-type circulation oil.

Metal Wire Mesh Making Machinery

Auto Chain Link Fencing Machine / Hexagonal Wire Netting Machine (Reverse

Twist) / Hexagonal Wire

Netting Producing Line (Gabion Weaving Machine & Equipments) /

High Speed Barbed Wire Machine / Wire Mesh Welding Machine

¡@

¡@

Home

Inquiry

Contact

automatic_net_making_machine.jpg)